30 x 25 x 15 cm

including GST

Watering can

Paint brush

Roller

Cement screeds

Mortars

Cement renders

Tile Adhesive

Watering can

Paint brush

Roller

Cement screeds

Mortars

Cement renders

Tile Adhesive

30 x 25 x 15 cm

Investing in waterproofing systems is always a big decision for homeowners and builders. It is important to have all of the information available surrounding the products that you’re about to use, the various types of systems, the installation processes, and the best deals on products for your situation. To learn more and receive personalised information, contact our team at Atech® products today by calling (03) 9028 4265 or leaving your details on our online contact enquiries form.

Atech® Products have had the full range of membranes tested and certified in NATA accredited laboratories to make sure that both liquid and sheet memberanes both meet Australian industry standards.

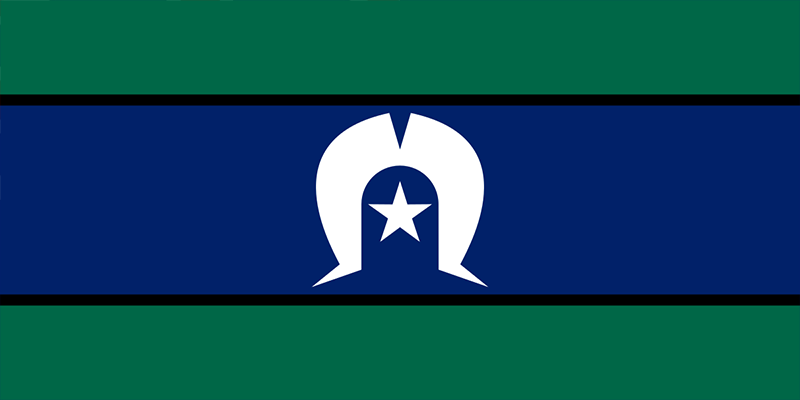

Atech® Products foundations are built for the future of the Australian building industry in making Australia a better place. Atech® Products proudly acknowledges the traditional owners and custodians of the land which we work and live. With their rich culture, we pay respect to Aboriginal Elders both past, present and future. Atech® Products strive for a future based on sustainability, and assisting Australians to build in a way that helps generations to come.

©Copyright 2023 • ATECH® Products

Please fill in the form and our friendly team will be in touch